S&OP is like any other business process/ improvement initiative – if it does not produce real business value; why do it? In this post we explore; “What value does S&OP create?” The identified values will be recognized from four perspectives recognizing S&OP as:

– Facilitator: Acting the vehicle to mature the Supply Chain beyond short term operational excellence

– Booster: Amplifies the impact of related business developing initiatives

– KPI driver: Drives forecast accuracy, increasing Customer Service Performance, and decreasing Inventory

– Cultural transformer: Fosters effectiveness and agility

S&OP – a quick refresher on purpose and definition

Before digging into the value S&OP creates, we brush up the general understanding of S&OP (if you want a more thorough refresher; check out our blogpost on The Basics of S&OP).

Supply Chain excellence is generally expressed in maturity models visualized as a ladder or a staircase, where the first step(s) is to get the short term planning in control; with a narrow focus to manage mix and meet service level targets. Climbing the staircase, the scope expands to cost and inventory optimization. However, limiting planning to the short time horizon, there is a threshold to how good you can get. To address and proactively change the preconditions for the short-term planning, the time horizon must be extended to fill the gap between Detailed and Business planning. S&OP fills that gap by planning on a 18-24 months’ horizon.

S&OP amplifies the impact of related business developing initiatives

S&OP provides mid and top management a tool to regularly follow up and track business development initiatives, e.g. New product development, Lean manufacturing and 6Sigma. Business developing initiatives generates business value in themselves. But, best in class S&OP practitioners get more, they leverage the S&OP process as “a control room” for the initiatives amplifying the output between 25-50%[1].

S&OP drives forecast accuracy, increasing Customer Service Performance and decreasing Inventory

S&OP is never implemented in a static environment – generally other initiatives are launched concurrently, making it difficult to exact size S&OP impact on planning performance, customer service, inventory levels (cash flow) and costs. Still, successful practitioners report major S&OP effect[2]:

- <90% forecast error decrease

- 10-40% on-time delivery improvements

- 12-70% inventory reductions

Theoretically, improvement in forecast accuracy drives impact on Customer Service (on-time delivery) and Inventory Reductions. The classic “Reorder-point formula” constitutes one way to link Forecast accuracy improvements to Customer Service and Inventory level performance; the higher forecast accuracy:

- The lower primary stock (average forecast demand * lead-time)

- The lower safety stock (demand error * safety coefficient, that depends mostly on the service level)

S&OP fosters effectiveness and agility

The soft sides of S&OP cannot be quantified. However, we believe that soft benefits eventually drive performance of hard KPIs. S&OP is recognized to make people more effective and agile.

The structure of S&OP covers elements which make people more effective:

- Cross functional communication – facilitated through “the one set of numbers”/ commonly accepted data and the structure with clear forums, tasks and expectations

- Empowerment – as decision-making is pushed down; with clear mandates and guidelines for decision

- Clear responsibilities and enforced accountabilities – as recurring agenda items in all S&OP meetings involve; KPIs and action-lists – monitoring and follow up

The S&OP process provides pre-conditions for an agile mindset as it fosters:

- A proactive, rational mindset – S&OP establish visibility and data driven decision making departing from “a unified data model”. Allowing to early detect sign of changes in the internal as well as external environment

- To take the cross-functional perspective – S&OP connects operating objectives and business strategies

- Flexibility in responding to customer requests and business opportunities – S&OP gets rid of suboptimization: establishing shared objectives and extended visibility

Summary

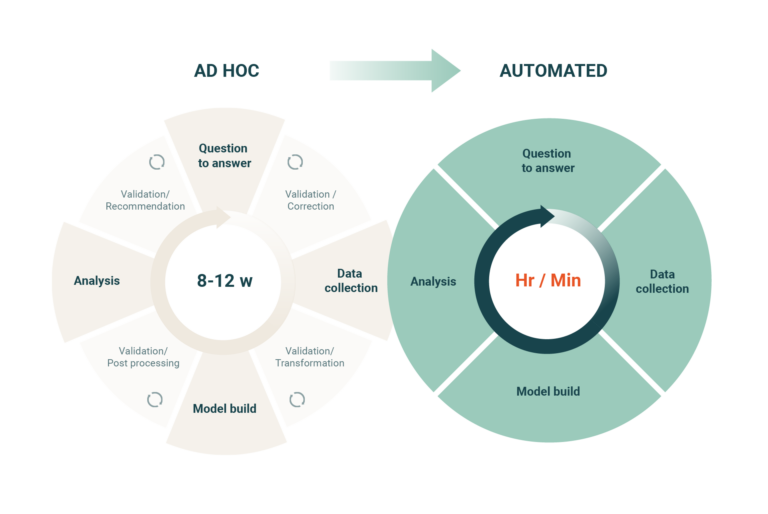

It is indisputable that S&OP creates value, still like any other business initiative – it should be challenged on value creation. Key ingrediencies of S&OP is workflow management, data consolidation and analysis, ingrediencies which could easily transform into time consuming exercises with limited value. To avoid getting stuck in managing necessities of a S&OP (data gathering, process steering, follow up in action items etc) We @Optilon offers a platform to support and steer the S&OP process, allowing the participants to focus on analysis and solutions.

Would you like to learn more about our approach to S&OP and Supply Chain planning from an end-to-end perspective then we invite you to take a closer look at our whitepaper which you can download for free right here:

[1] Dougherty, John and Gray, Christopher. Sales and Operations Planning – Best practices Lessons Learned From Worldwide Companies. Belmont: Partners for Excellence, 2006.

[2] Dougherty, John and Gray, Christopher. Sales and Operations Planning – Best practices Lessons Learned From Worldwide Companies. Belmont: Partners for Excellence, 2006.