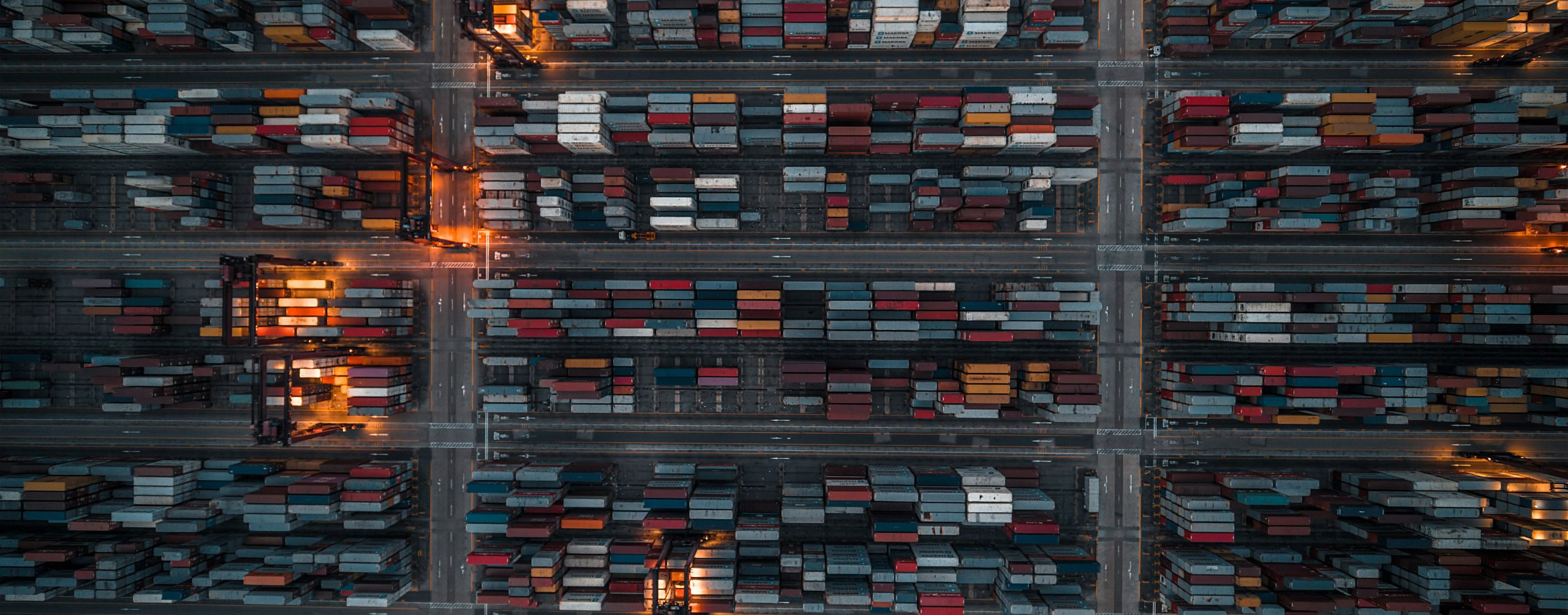

In our previous article, The €23 billion inventory trap – how did we get here? (Part 1), we exposed a hidden challenge costing Nordic companies a staggering €23 billion. This is unnecessary inventory that’s weighing down operations, tying up capital, and inflating environmental footprints. The good news? Problems create opportunities — and in this case, the opportunity is massive. So, how exactly do you turn €23 billion worth of “waste” into a competitive advantage? Let’s dive in.

3 inventory optimization strategies for smarter supply chains

If you’re looking to take control of your supply chain, cut down on waste, and free up valuable capital, it starts with rethinking how you manage inventory. We’ve seen it firsthand — when companies start treating inventory as a strategic asset (not just stuff in storage), everything changes. Here are three strategies that can help you turn excess stock into a real competitive advantage. Let’s explore them together.

1. AI-driven forecasting: Predict demand with precision

Let’s be honest: guessing isn’t a strategy anymore. If you’re still relying on outdated forecasting models, chances are you’re either drowning in stock or scrambling to meet demand — and both are costing you more than they should.

But it doesn’t have to be that way. When you put AI to work in your forecasting, you can:

- Analyze real-time data from multiple sources.

- Accurately predict demand patterns.

- Fine-tune replenishment cycles and production schedules.

In other words, you stop reacting — and start anticipating. That means no more stockouts. No more overstocking. Just the right products, in the right place, at the right time.

The result? Less capital tied up, better product availability, and a more agile supply chain – ready for whatever comes next.

2. Lean inventory strategies: Finding the right balance

Keeping extra inventory “just in case” might feel like a safe move — but in reality, it’s silently draining your resources and slowing you down.

A smarter approach? Shift your mindset from “just-in-case” to “just-in-time”. That doesn’t mean cutting to the bone. It means being more strategic with what you stock, and where.

Here’s how you can get started:

- Segment your inventory based on demand patterns and product importance.

- Prioritize fast-moving items while minimizing slow-movers.

- Use modern warehouse systems to streamline processes and optimize space.

With lean inventory strategies, you’ll boost service levels while lowering inventory costs — giving your business more flexibility and a healthier bottom line.

Curious about what this could mean for your business?

3. Sustainable supply chains: Reducing waste and emissions

Inventory optimization isn’t just a financial decision – it’s a sustainability strategy too.

Every unsold product represents wasted resources: materials, energy, transportation, storage space, and eventually, disposal costs. Not to mention the environmental impact.

As customer expectations rise and regulations tighten, your supply chain needs to do more than deliver — it needs to deliver responsibly.

Here’s how you can align efficiency with sustainability:

- Cut emissions by reducing overproduction.

- Optimize transportation and storage to reduce environmental impact.

- Invest in green transport, circular processes, and smarter production cycles.

In short, efficiency and sustainability no longer compete — they complement each other. And when you build a supply chain that supports both, you don’t just meet expectations — you lead the market.

Ready to unlock your supply chain’s hidden power?

Inventory isn’t just stuff sitting on a shelf. It’s a powerful lever — if you know how to pull it. Mastering inventory optimization means more liquidity, greater resilience, stronger sustainability performance, and a sharper competitive edge.

Next up in The Future of Inventory Optimization – Sustainability and Resilience (Part 3), we’ll show you how to make these wins stick – and how your supply chain can drive lasting success. Don’t miss it – click through and see what’s next!

Haven’t read Part 1 yet? You’ll find it here.

Want to read the full Unnecessary Report?